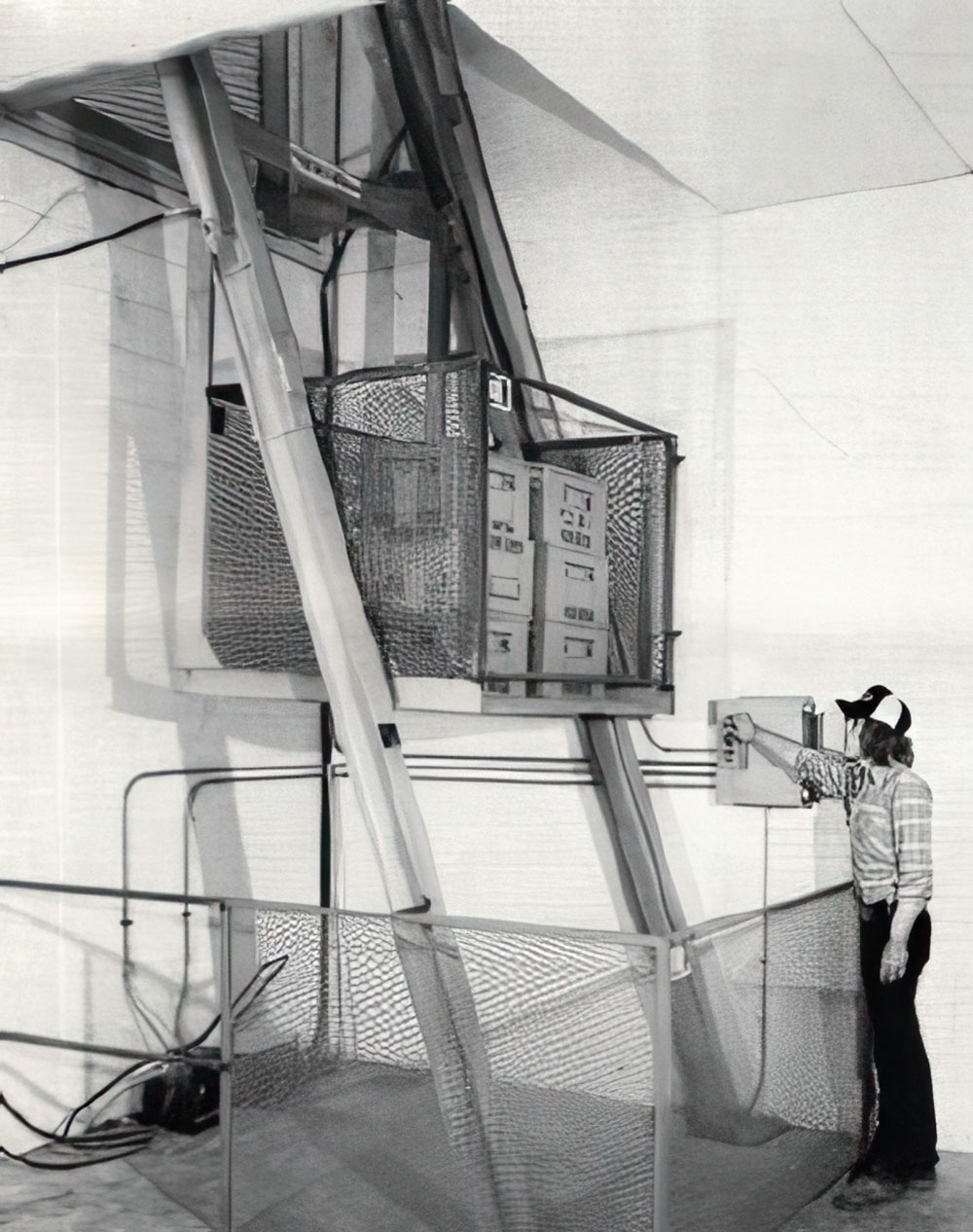

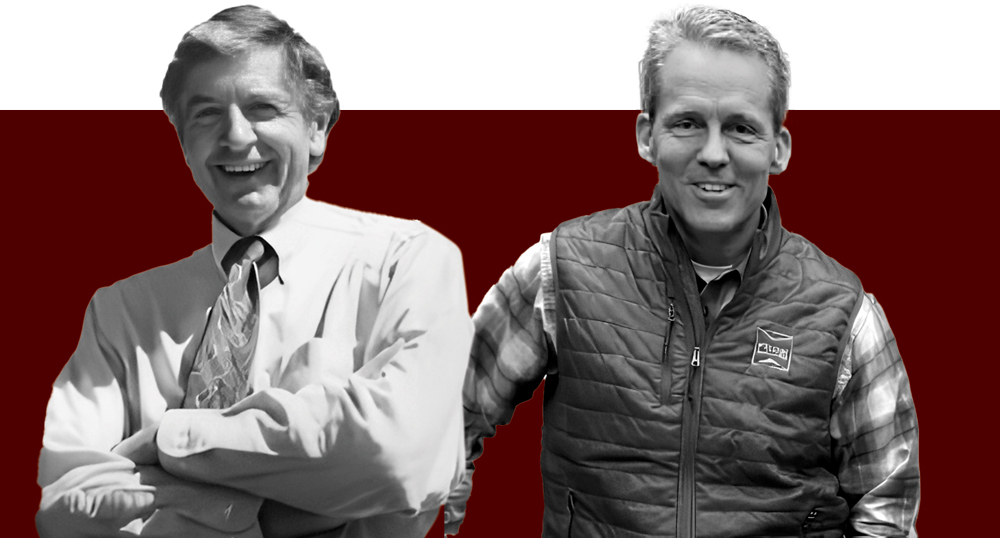

t was 1977 when Bob Pfleger decided to leave a successful 20-year career in the dock business at The Kelley Company and venture out on his own. His idea: manufacturing inclined vertical conveyors oriented at a 70-degree angle to move materials. He incorporated PFlow Industries and quickly brought his long-time friend and coworker Herb Ruehl on board.

Within a year, elevator inspectors began shutting down operation of PFlow’s incline lifts, insisting they did not comply with elevator codes. PFlow fought back, arguing its conveyors moved materials, not people, and should not be held to the same code requirements. In 1981, the ASME ruled in PFlow’s favor, but state and local agencies continued to push back.

While the fight with the elevator industry continued, fueled by determination and innovation, Pfleger pioneered the vertical reciprocating conveyor (VRC)—a versatile material lift that redefined multilevel material handling. PFlow VRCs quickly became a go-to solution across industries, from factories to the fast-growing self-storage industry. By 1987, PFlow had prevailed in having VRCs be governed in all 50 states by the ASME B20.1 conveyor code instead of the A17.1 people-moving code.

Helping fill the void was Ruehl’s son, Ted, who joined PFlow in 1981 and had already been playing a key leadership role. Ted was instrumental in purchasing the 125,000-square-foot former Kelley Company building, where Pfleger and his father worked side by side for 20 years. “I wish Bob had been alive to see it happen; he would have been thrilled to be the owner of his former employer’s building,” said Ted. Growth continued with a 21,000-square-foot neighboring building to accommodate expansion.

In 2019, Ted was named CEO and Pat Koppa joined as president, marking a new chapter in PFlow’s leadership. Today Pfleger’s legacy lives on through the “PFlow PFamily,” who carry forward his vision of delivering exceptional products and fostering a culture that is driven to get the job done.

Although there are fewer regulatory requirements when moving materials versus people, Hext explains that VRCs still incorporate a range of code-required and optional safety features that help protect both the materials being moved and the people using the VRC. “Several states prohibit the operation of VRCs by the general public, so only authorized facility staff can operate the equipment, securing drop bars or gates and operating the push button controls to send the VRC to another floor level once loaded.”

Hext says VRCs have become very popular in building conversions. “Because they’re regulated under conveyor code, they avoid many costly rider-safety provisions and frequent code-required inspections, which can result in a lower lifetime cost of ownership—a win for your budget and tenants!”

Of course, every facility has its own challenges, but Hext says PFlow VRCs overcome them. “No two PFlow VRCs are alike—each is engineered around a facility’s specific requirements, from carriage size and capacity to the number of floors it serves and the exact way goods are loaded and unloaded at each level.”

While freight elevators require concrete fire-rated enclosures or dedicated machine rooms, VRCs can allow for more flexibility in placement because they do not have these structural requirements.

“A VRC can be integrated seamlessly inside a building or placed on the exterior, where it can be enclosed against the elements without consuming valuable rentable square footage,” says Hext. “By tailoring every system to operational needs and physical space, PFlow delivers material lifting solutions that improve efficiency and safety while maximizing the return on every square foot of your facility.”

The right VRC starts with understanding your space and operations. “We have a nationwide network of material-handling dealers who conduct on-site visits to review facility layout,” says Hext. “We provide a tailored quote, and once approved, our engineering team designs a custom lift that fits those exact operational and space requirements.”

Where does PFlow go from here? According to Hext, “From the day Bob started PFlow, we’ve continually redefined how materials move. Whatever materials you need to lift, PFlow engineers safe, efficient solutions tailored to your operation. While our technology evolves, our commitment remains the same: delivering the industry’s best lifting solutions, backed by world-class service and support.”